EXHALE

Amsterdam, The Netherlands

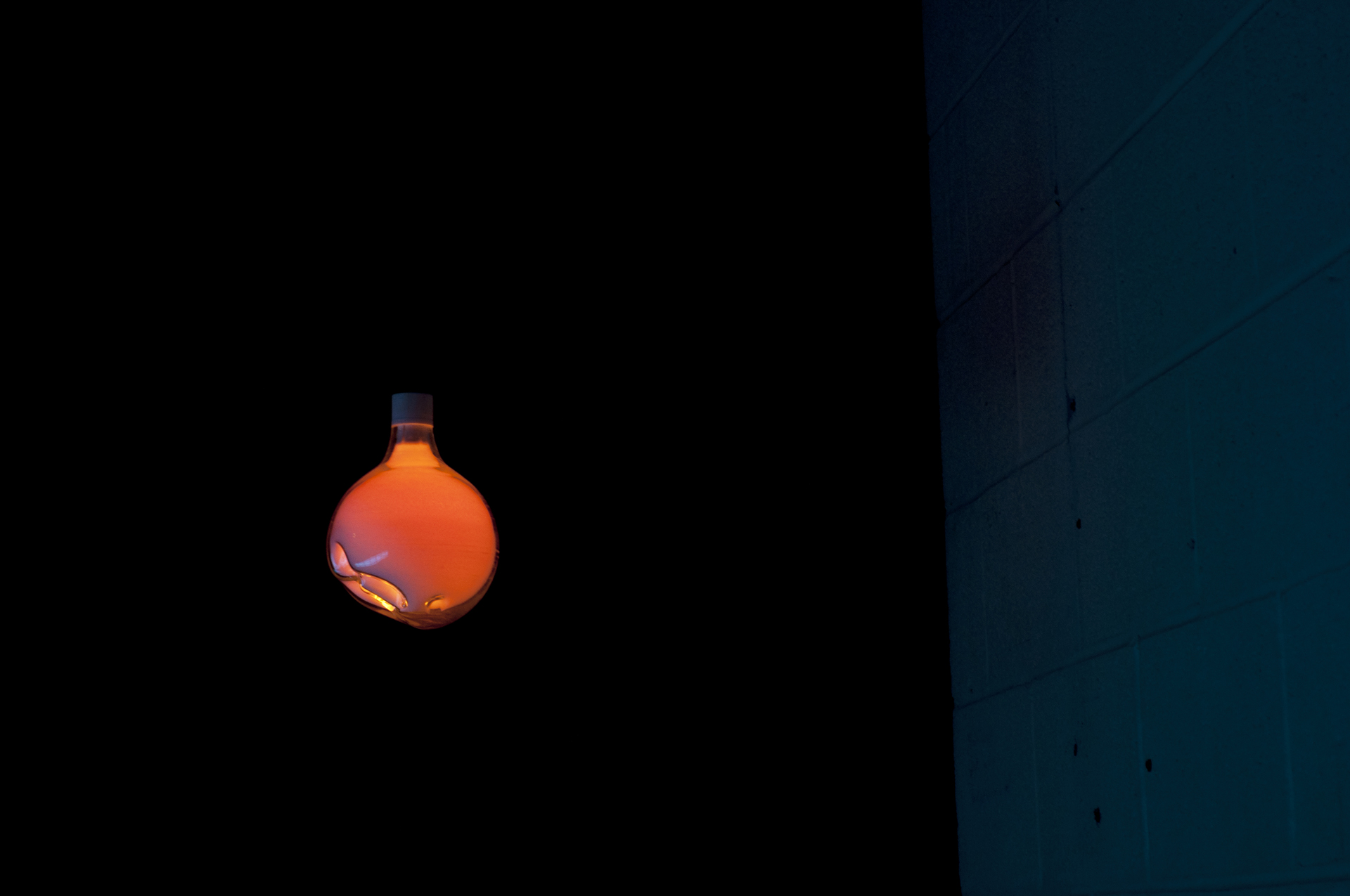

Exhale skillfully encases a single blow of glass within a rigid metal structure. The metal form restricts the glass by pinching, hooking and spiking into the volume during the blowing process, capturing a tense play between the constricting and billowing materials. The entire fixture catches one breath.

Exhale, undertaken in partnership with Wes McGee and blower Brian Barber, creates deep physical resonance between strength, fragility, and the fleeting breath that brings them together.

Project assistants: Matt Culver, Kelly Gregory, Emily Kutil

Exhale is available with WDSTCK.

DIFFUSE GLOBES

Detroit, Michigan

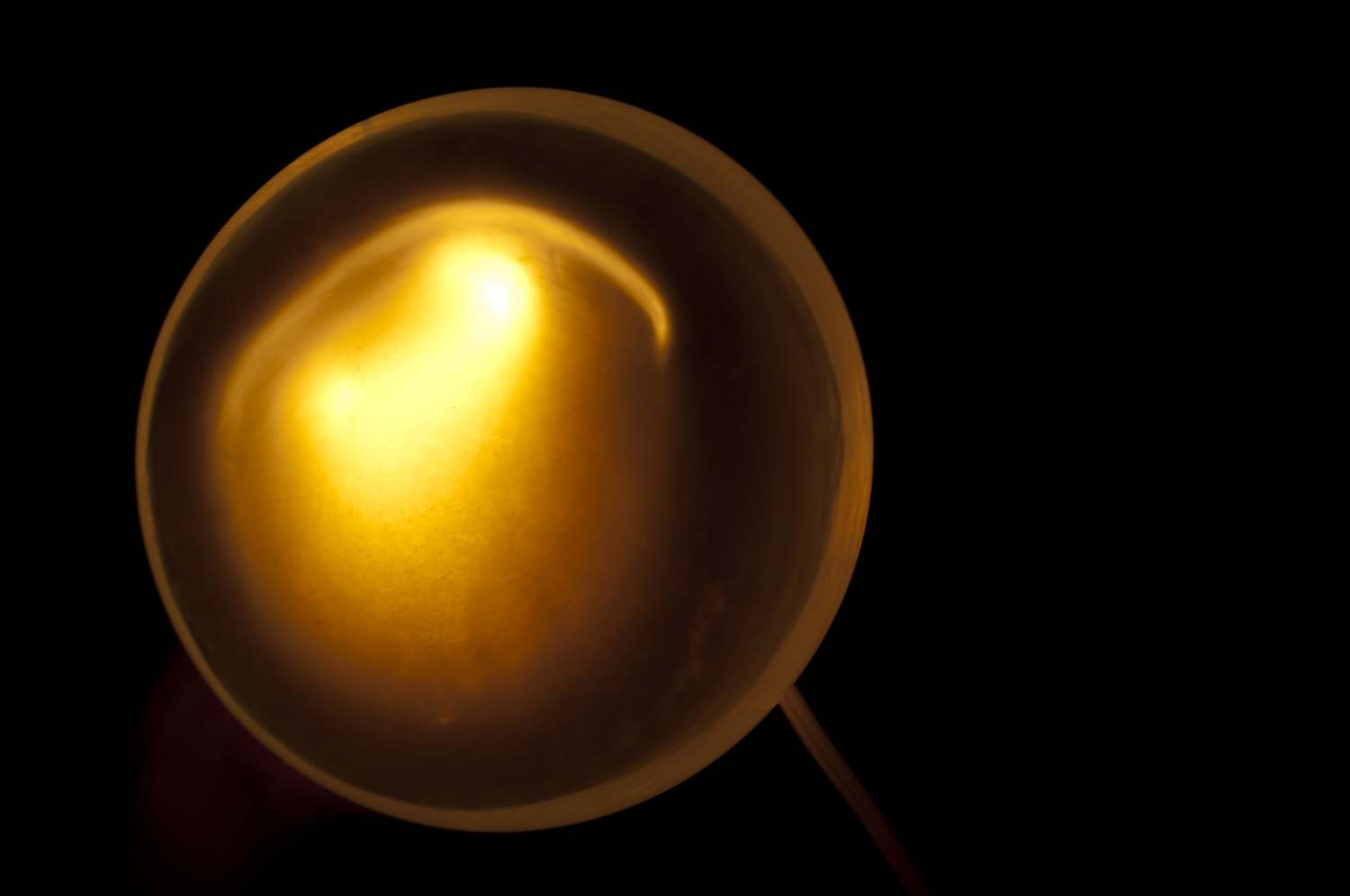

The Diffuse Globe light series alters a specified blown glass globe through custom forming to control the dispersion of light, providing variation and distinction to otherwise generic light bulb forms. Encasing a low wattage bulb within the fixture, the medium within the globe diffuses the light source, diminishing the perceived glow at the outer edge of the globe. To control the directionality and intensity of the light, each globe is uniquely deformed during its fabrication. Internal depressions allow for the concentration of released light while protrusions increase the scatter, locally attenuating it. As a result of manipulation techniques inflicted on the glass during its forming, each Diffuse Globe takes on its own character and presence that through its unique derived dispersion of light implicates a relationship to surrounding space and occupants.

The fabrication methods for the Diffuse Glove series strategically utilizes digital technologies and long-established glass blowing techniques. Encompassing the latent materiality of glass as an amorphous solid, the developed techniques incorporate rigor and refinement with spontaneity and variation while working with the malleability of glass during forming and its physical attributes upon cooling. To establish a base form from which to manipulate, CNC-milled positives are cast in white gypsum cement to create a reusable negative mold. Base glass blanks are mold-blown and manipulated with manual forming tools that are developed with a sensibility to characteristics present at forming temperatures and the resulting relationship between form and illumination effects. The tools, designed with T-splines in Rhino and CNC-milled out of metal stock, are made to allow for multiple moments of contact and variable means by which to interact with the glass. Upon annealing, each Diffuse Globe is fitted with an existing internal lights source. In order to allow for the variability produced by the manual process of glass blowing, the sockets, which feature an innovative internal-external strain relief, are parametrically designed and digitally manufactured to fit each individual globe. The pairing of analog and digital processes harnesses the distinct potential for variability permitted within each realm of making while also permitting a refined technical operation interrogating the connections between craft and explicit control.

Often such variability comes at great costs for fabrication, requiring numerous molds or waste. Conversely, the variations within the Diffuse Globe series enters at a moment in the sequence when the material can be directly manipulated placing the variability within the fine details of the process, and not in the tooling, so it produces no waste. During the manufacturing process, even if the glass breaks or becomes unruly, all mistakes can be returned to the material batch. Further, all the materials in the process, from tools and molds to resultants, have been developed for their reusability. A parametric modeling output for the sockets pairs the unique wall thickness of each blown globe with perfectly fit socket and strain relief connection.

The light effects, and directionality of each Diffuse Globe, prompt variability in installation and intention for use.

Funding:

Research through Making Grant from the Taubman College of Architecture and Urban Planning

Office of the Vice President for Research, The University of Michigan

Project Team:

Catie Newell of *Alibi Studio and the University of Michigan

Wes McGee of Matter Design Studio and the University of Michigan

Glass Expert:

Lucy Olechowski

Fabrication Team:

Aaron Willette

Jason Psad

Mark Meier

Grant Weaver

Simon Rolka

Patrick Ethen

Schmoe

The making of the Diffused Globes can be seen in the second half of this film: {process film} by Stebs Schinnerer of Paper Fortress